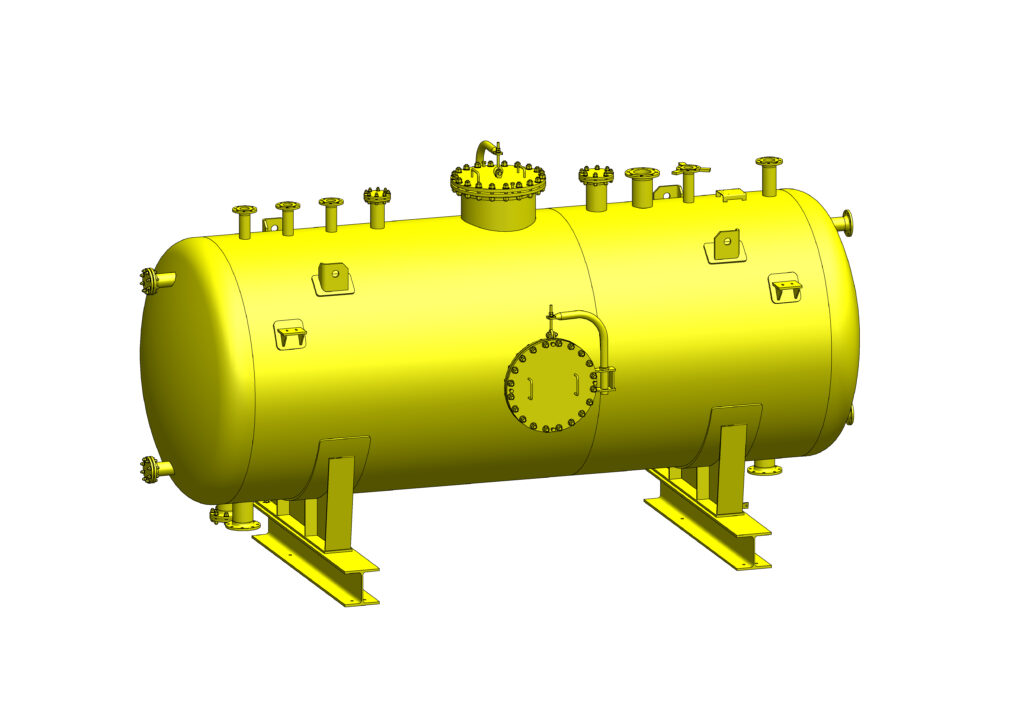

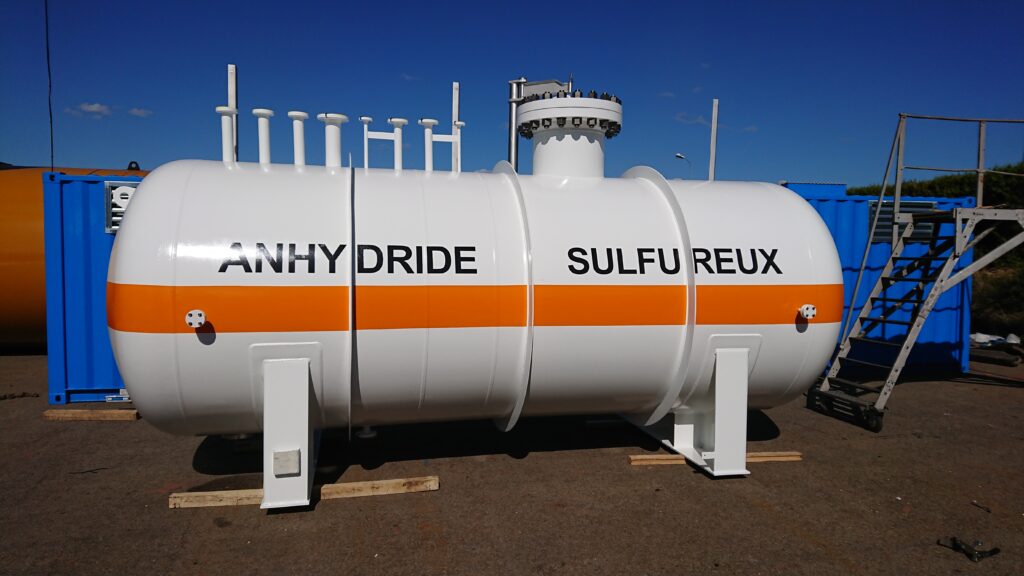

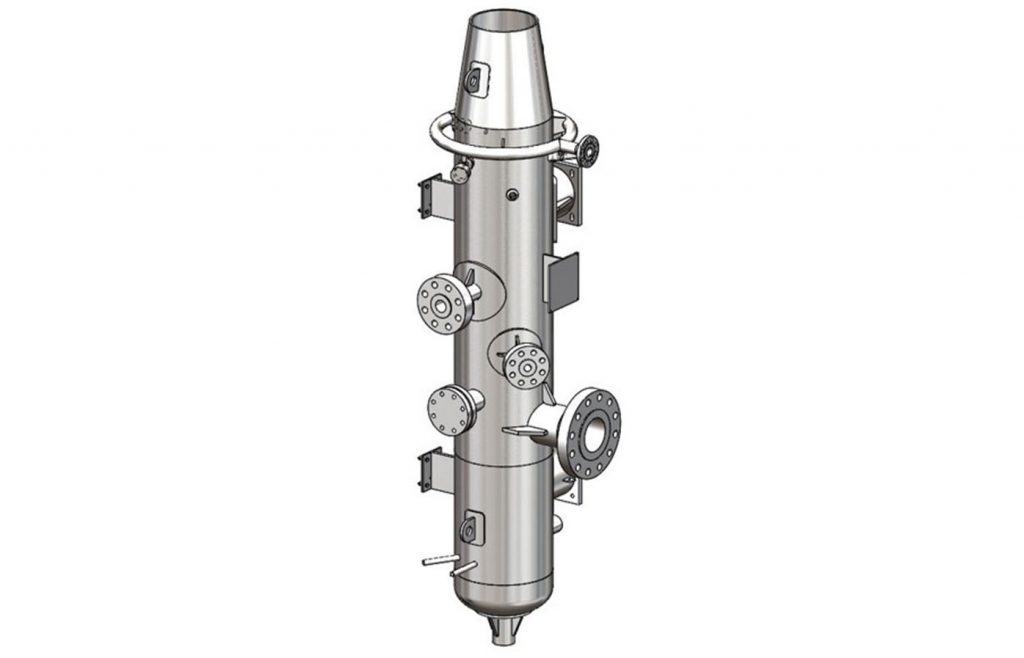

Pressure tanks

Pressure tanks subject to PED

The production of equipment subject to the Pressure Equipment Directive 2014/68/EU requires special quality monitoring and high quality welding.

Our dedicated design office and experienced boilermakers allow us to manage your ESP needs from design to completion

Materials: Steel and/or stainless steel

Thickness: Up to 35mm (depending on dimensions)

Pressure: -1 / +40 barg

PED classification up to risk IV – module G

Surface treatment: Pickling and passivation for stainless steel. Shot blasting and coating for steel.

We can also equip your tanks with :

- An agitation to facilitate suspension, homogeneous mixing and heat exchange

- Insulation in the workshop to save time during installation

- A temperature maintenance or heating capacity by coil or tracing

Codes & Standards

EN 13445

CODAP Division 1 ou 2

ASME VIII Div.1 (hors Stamp “U”)